cnc machine programming Computer numerical controlled (CNC) machine programming is a process whereby instructions are combined together to define how a CNC machine will move and function. By carrying out these instructions, the CNC machine will convert some form of raw material into a . Describe what "ganging" electrical device boxes is and what purpose ganging electrical device boxes serves. Ganging is the joining together of two or more device boxes for the purpose of holding more than one device.

0 · What is CNC Programming?

1 · Mill

2 · Introduction to CAD, CAM, and Practical CNC Machining for Milling

3 · G

4 · CNC Software for Machining and Manufacturing

5 · CNC Programming

6 · CNC Machining Software

7 · CAM software for CNC Machining

8 · Autodesk Fusion

9 · 3D CAD/CAM Software for Machinists

I'm thinking that it is the power distribution box (PDB), located in the engine compartment and is nolonger referred to as the Smart Junction Box (SJB). Also, since I last posted, I've realized that my power (gas and brake) .

Computer numerical controlled (CNC) machine programming is a process whereby instructions are combined together to define how a CNC machine will move and function. By carrying out these instructions, the CNC machine will convert some form of raw material into a .Autodesk Fusion software (formerly known as Fusion 360) provides professional-grade CAM tools to automate the programming of 2D, 2.5D, 3-, 4-, and 5-axis CNC machines.

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .CNC (Computer Numerical Control) machining software provides the interface for controlling, managing, and programming CNC machines. The software is used to create a set of instructions in the form of G-code or M-code, which guide the machine tools to perform the desired operations.

Access a range of powerful 3-axis machining strategies to rapidly create high-quality NC code to rough and finish your 3D parts. Intuitive workflows make it simple to program individual features or entire parts.Mill-turn programming software, like Autodesk Fusion provides tools and features to create CNC (Computer Numerical Control) programs for mill-turn machines. It allows users to define machining operations, toolpaths, and cutting parameters for both milling and turning operations.

What is CNC Programming?

CAM software for CNC machining. Start making today. Autodesk Fusion 360 software doesn't only control CNC machines on a shop floor, it brings together software, machines, processes and people to design and manufacture high-quality products on time, the first time. Learn more.

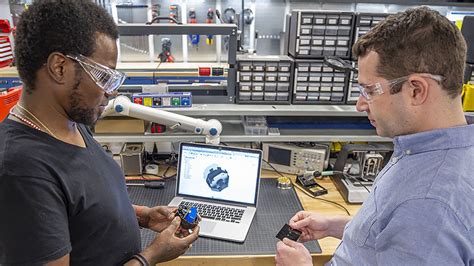

Computer-aided manufacturing (CAM) software helps people create programs for various CNC machines to support different manufacturing processes. These include milling, turning, turn-mill, cutting, probing, part inspection, additive manufacturing, and more. Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts.

Computer numerical controlled (CNC) machine programming is a process whereby instructions are combined together to define how a CNC machine will move and function. By carrying out these instructions, the CNC machine will convert some form of raw material into a .

Autodesk Fusion software (formerly known as Fusion 360) provides professional-grade CAM tools to automate the programming of 2D, 2.5D, 3-, 4-, and 5-axis CNC machines.

Mill

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .CNC (Computer Numerical Control) machining software provides the interface for controlling, managing, and programming CNC machines. The software is used to create a set of instructions in the form of G-code or M-code, which guide the machine tools to perform the desired operations.

Access a range of powerful 3-axis machining strategies to rapidly create high-quality NC code to rough and finish your 3D parts. Intuitive workflows make it simple to program individual features or entire parts.Mill-turn programming software, like Autodesk Fusion provides tools and features to create CNC (Computer Numerical Control) programs for mill-turn machines. It allows users to define machining operations, toolpaths, and cutting parameters for both milling and turning operations.

CAM software for CNC machining. Start making today. Autodesk Fusion 360 software doesn't only control CNC machines on a shop floor, it brings together software, machines, processes and people to design and manufacture high-quality products on time, the first time. Learn more.Computer-aided manufacturing (CAM) software helps people create programs for various CNC machines to support different manufacturing processes. These include milling, turning, turn-mill, cutting, probing, part inspection, additive manufacturing, and more.

Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts.Computer numerical controlled (CNC) machine programming is a process whereby instructions are combined together to define how a CNC machine will move and function. By carrying out these instructions, the CNC machine will convert some form of raw material into a .Autodesk Fusion software (formerly known as Fusion 360) provides professional-grade CAM tools to automate the programming of 2D, 2.5D, 3-, 4-, and 5-axis CNC machines. Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

Introduction to CAD, CAM, and Practical CNC Machining for Milling

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .CNC (Computer Numerical Control) machining software provides the interface for controlling, managing, and programming CNC machines. The software is used to create a set of instructions in the form of G-code or M-code, which guide the machine tools to perform the desired operations.

Access a range of powerful 3-axis machining strategies to rapidly create high-quality NC code to rough and finish your 3D parts. Intuitive workflows make it simple to program individual features or entire parts.Mill-turn programming software, like Autodesk Fusion provides tools and features to create CNC (Computer Numerical Control) programs for mill-turn machines. It allows users to define machining operations, toolpaths, and cutting parameters for both milling and turning operations.CAM software for CNC machining. Start making today. Autodesk Fusion 360 software doesn't only control CNC machines on a shop floor, it brings together software, machines, processes and people to design and manufacture high-quality products on time, the first time. Learn more.Computer-aided manufacturing (CAM) software helps people create programs for various CNC machines to support different manufacturing processes. These include milling, turning, turn-mill, cutting, probing, part inspection, additive manufacturing, and more.

multi axis cnc machining

mr foodie stainless steel lunch box

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding.

cnc machine programming|Autodesk Fusion